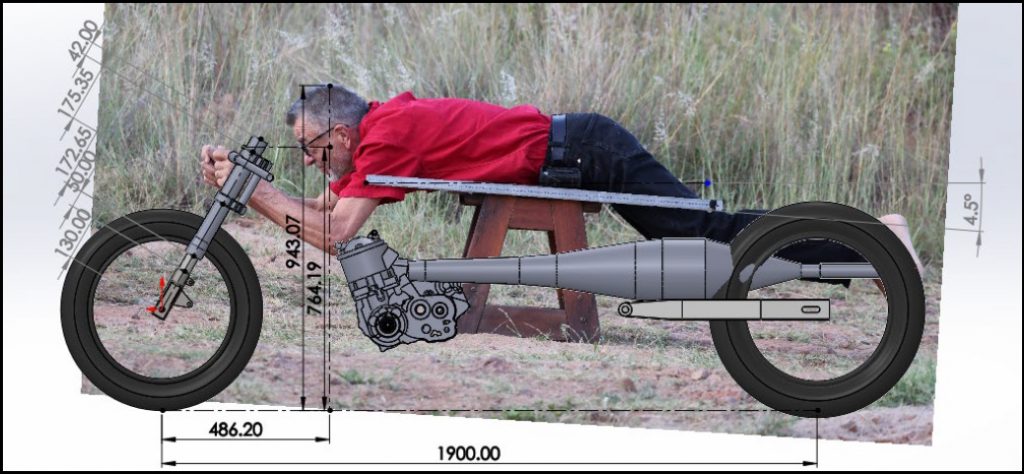

Below is a side view of our first bike layout concept dating back to April, the idea was to reduce frontal are for best possible top speed. Mmmmm, lots of issues here!

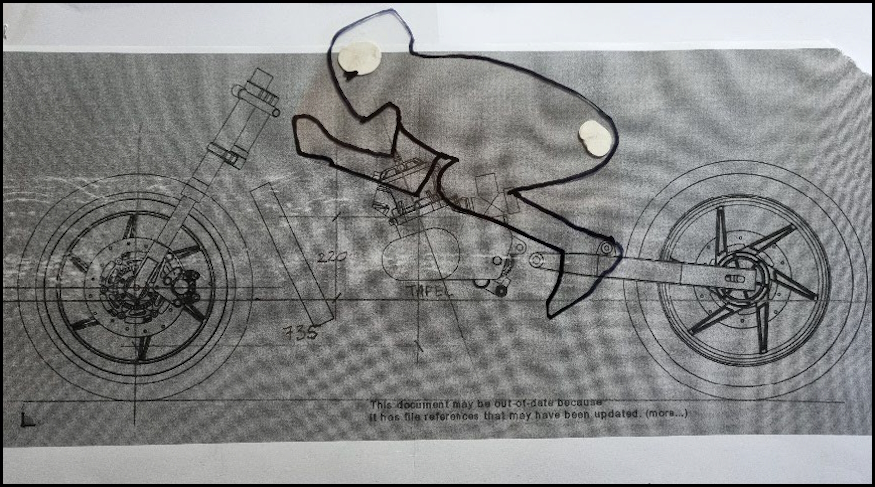

After thinking about the prone riding position a lot, we decided to do something more conventional, the next pictures date back to July. The main reason for abandoning the prone concept was that I am a bike racer and I need to ride in a position that I’m accustomed to so that I have a better chance of controlling the bike when the ruts in the salt pan throw me a curve ball! It should be noted here that the last time I rode a bike in anger was 33 years ago, virtually nothing in between…..

Below follows a quick photo story of the first real world optimisations of my riding position when I started fabricating the frame in November. We strive for minimal frontal area to improve our top speed at Bonneville in August 2024. Land speed records stand and fall by wind resistance and horsepower. We have a great engine design, tuning and optimising of the engine can only start next year when the engine is built and running. Wind resistance is critical and we can do something about it right now, my racing journey has officially begun!

This is riding position 1, feet tucked in (I wear size 14 UK boots so it’s important!) and I’m squinting over the triple clamps. The forks are pushed up as far as possible to lower overall height but leaving just enough space for the front wheel not to touch the bottom triple clamp at full bump.

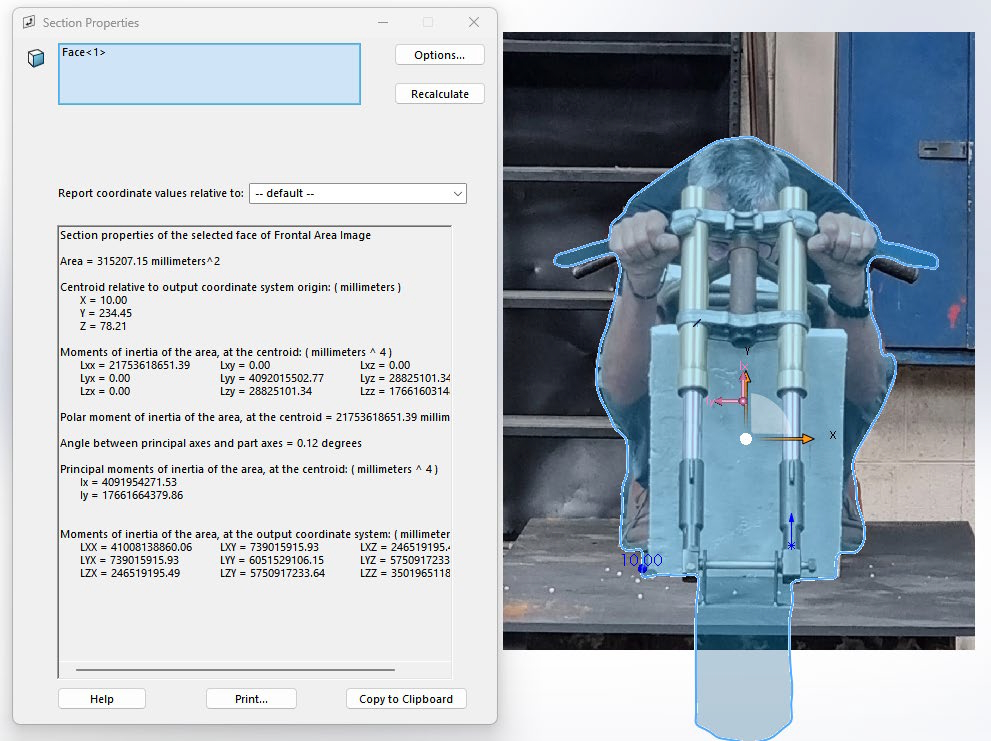

The view the wind will have of the bike and me. The white polystyrene sheet is a place holder for the future radiator.

Version 2: I moved further back, added a rusted pipe to simulate the rear wheel so I would know not to move too far back and I got my head further down so I squint underneath the triple clamps to lower my profile.

The wind’s view, note my knees sticking out further than my arms, not good.

Version 3: I fitted a thinner base under my chin to lower my head even further.

I nipped and tucked the main frame spars so my knees could move inwards and not stick out so much, looking better and better!

The nip and tuck process, first I mitred the uprights and then heated and bent the frame spars to meet the angled uprights, lekker!

Jock used the final picture to calculate total frontal area on CAD which we plugged then plugged into the simulation program to calculate top speed. The great news is that this area is substantially smaller than what I have used until now and our top speed jumped up by 20 km/h just because of this more accurate and smaller figure!

Our drag coefficient is still a “guess” at 0.7 and this is equally important to calculate a top speed that will be close to what actually happens at Bonneville. Getting real world power curves from the dyno once the engine is running is the next major factor to allow us to predict something close to the real experience.

I contacted Dr, Becker van Niekerk at Bronberg Dynamics this morning and with his help we will stuff PZ500 in either his or the CSIR wind tunnel and get more believable drag figures to plug into our simulation program!

Work is ongoing on many fronts, I feel we are getting ever closer to start testing PZ500 in real life, this is tremendously exciting and I can hardly wait for our first rumble in the jungle north of Moloto in the next months!

PeeZee greetings

KooZ

17 November 2023